Emitter Section Tube

The measurements given here are taken from my finished saber. Don't

be afraid to change them to suit yourself.

Take 1-1/2 x 6" extension tube. The cap and washer are not needed.

Using your rotary tool (Dremel) and a cut-off wheel, cut the threaded end

off getting as close to the threads as possible. If you cut it close enough,

you will be left with a little flare to the very end of the tube that will

give you a nice look, and make later assembly easier. This

is a good place for me to say my piece on rotary tools and other power

tools: If you are using a power tool then please wear some safety goggles.

Believe me, building this project you will need them. They're cheap, so

pick up a pair at Walmart or the dollar store. -Brian.

Using your rotary tool (Dremel) and a cut-off wheel, cut the threaded end

off getting as close to the threads as possible. If you cut it close enough,

you will be left with a little flare to the very end of the tube that will

give you a nice look, and make later assembly easier. This

is a good place for me to say my piece on rotary tools and other power

tools: If you are using a power tool then please wear some safety goggles.

Believe me, building this project you will need them. They're cheap, so

pick up a pair at Walmart or the dollar store. -Brian.

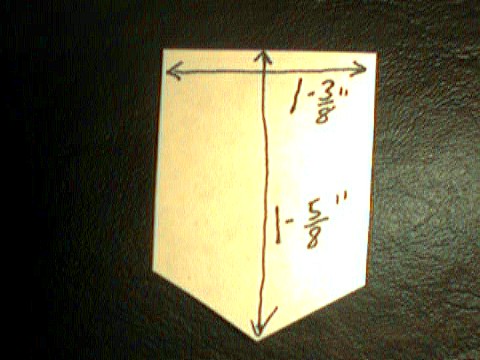

Now take the same tube you just cut and and cut the narrow end off so that

its total length is about 3-2/8". I took these pictures

after taking apart my completed saber so just ignore the activators and

finishing washers for now.

Now take the same tube you just cut and and cut the narrow end off so that

its total length is about 3-2/8". I took these pictures

after taking apart my completed saber so just ignore the activators and

finishing washers for now.

If you're having problems getting straight cuts on the tube, try wrapping

the tube with lined notebook paper. You can line up the lines and then

tape it down with masking tape giving you a good guide to cut by. It's

also good to wrap your tube with masking tape around your cutting area

to protect the finish if your rotary tool slips or jumps (it

will!). Also, for these cuts that run the circumferance of the tube,

you'll find that the larger diameter cut-off wheels are easier to cut with.

They allow you to hold the tool farther from the tube and still get the

right angle.

Now you want to cut the emitter vents in the tube. You should cut these

into the large flared section of the tube. The patterns are basically rectangles

with one side extending to a shallow point. If you want yours to be more

accurate(than mine) then you should cut small slots (about 3/16" deep x

2/16" wide) extending the point of the vent opening. There are three vents

spaced evenly around the tube with their leading edges about 3/16" from

the end of the tube. Make yourself three paper patterns and tape them to

the tube for cutting.

Cutting these vents are a real pain, but just remember that you can

always clean up the holes with a grinding or sanding attachment on the

rotary tool, so err on the side of cutting too little, rather than too

much.

Home Style

#2 Parts List

Emitter Tube Base

Tube Grip Tube

Pommel Tube Clip

Knob Emitter Assembly

Grip Assembly Pommel

Assembly Finishing

Touches Email

Me